Proper Race Car Wiring Principles

Download full Article PDF Here

With the never-ending quest for more horsepower and faster cars, today’s racecars have more electronics than ever. To create more horsepower, cylinder pressures must rise. To fire the cylinders under these higher pressures, modern ignition systems are more powerful than ever. This powerful spark, requires powerful drivers. Ignition boxes can easily pull 40 amps or more from your electrical systems. This combined with other systems in your car like solenoids used to control converters, nitrous, boost, etc. put an extremely high demand on your car’s electrical system. This has forced us to rethink the way the cars are wired and to consider basic electrical principles like Ohm’s Law.

Some wiring guys or shops know what they’re doing and do nice neat work that also follows the techniques outlined here to insure a proper install of all your equipment. However, many think that a ground is a ground and power is power, as long as it turns on/off then the job is done. If this is the case with your installer, then get ready for problems. We often see beautiful wiring jobs that do not follow these basic electrical engineering practices, leaving the customer with problems at the track that waste thousands of dollars in missed runs, or even damaged components and engines!

The way that power is distributed between your electrical systems and your electronics can be critical to the proper operation of your electronic devices. Wire size is important to prevent voltage drops or voltage “brown-outs”, but the way the various instruments and electrics are connected and the connection paths are also critical.

Problems can occur when an electronic device and an electrical device such as a motor or solenoid share a common electrical path (power, ground or both).

While an electric motor or light bulb might draw 5 amps when it’s running, it can draw much more current when starting. A 5-amp solenoid may draw many times that when engaging, causing a momentary spike on the power and ground buses where it’s connected. This voltage drop or “transient” might last only a few thousandths, hundredths, or tenths of a second and you might not even notice it. The solenoid will likely operate just fine, with no known issues, but some of the other electronics may not like the voltage drop and malfunction, causing reset or lockup. This may be a very brief event but can ruin your day at the track for sure.

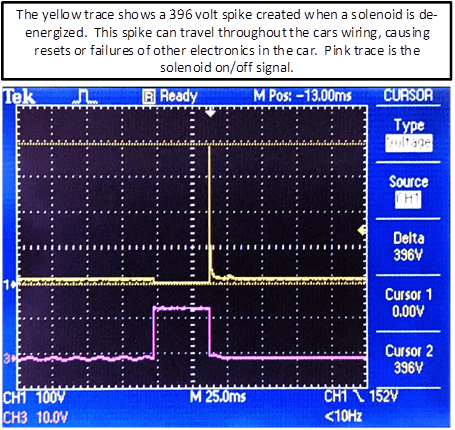

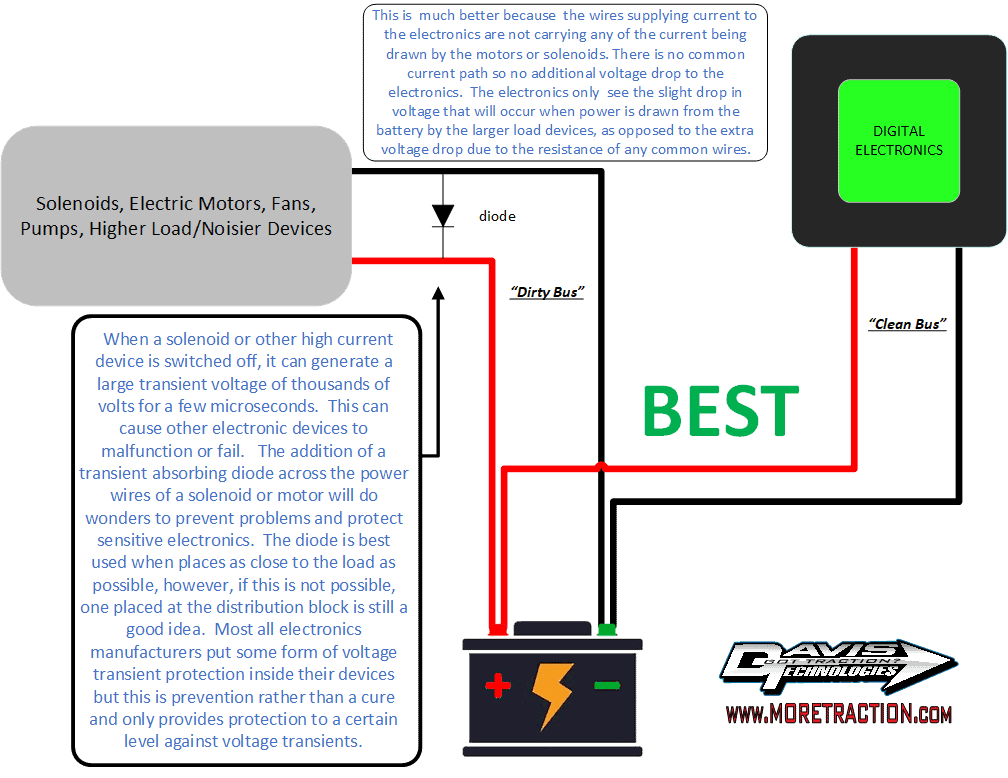

Transients can occur when you turn OFF devices such as motors or solenoids. Energy stored in the magnetic fields of these devices can create voltage spikes of hundreds of volts when the power is suddenly removed as the magnetic energy is instantly converted back to electrical energy by the collapsing magnetic field. These spikes occur when the motor or solenoid is turned OFF not ON. These very fast voltage spikes usually do no damage to electrical devices but can destroy electronics or cause them to do things you don’t expect or want. Data corruption of memories or corruption of the software being run in microcomputers and even destruction of parts of the electronics are often the result of poorly wired circuits.

Devices installed in a race car should be divided into two categories: power devices and control devices.

Power devices are things that use a lot of current for brute-force operations like turning on solenoids and generating ignition sparks. They will generally have large-gauge, “fat” wires for power connections.

Control devices are things that make decisions and send and receive low-current signals like logged data and ignition timing triggers. They will generally have smaller-gauge wires for power connections.

Some devices will fall into both categories, like an ignition box that both generates sparks and receives a low-current signal to know when to generate said sparks. Often you will find that these devices have two sets of ground and/or power wires. There will be a large-gauge set for the power section and a small-gauge set for the control section.

Voltage Drops

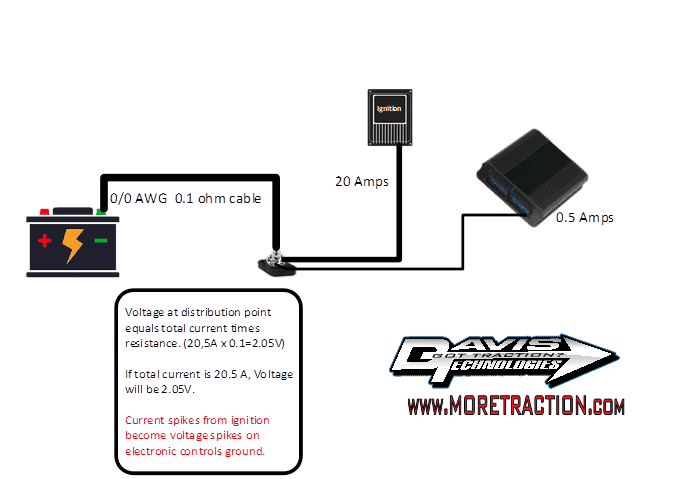

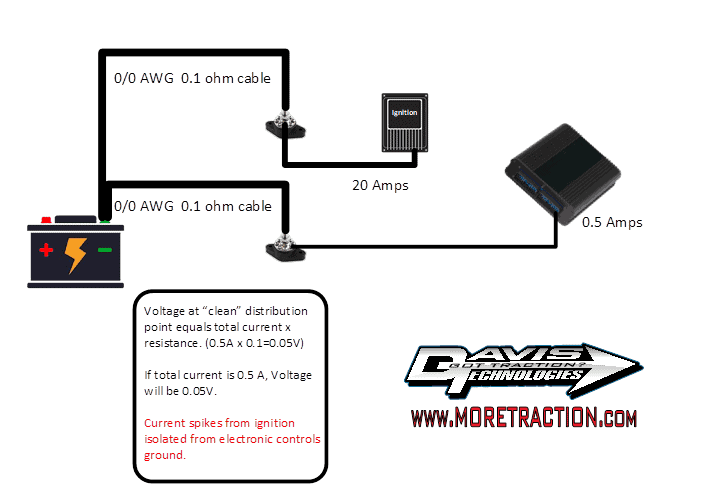

Most of us have used an ohmmeter to measure resistance. We learned that a very low resistance is a “dead short”. In today’s race environment, however, it might serve us to revise that perception. When very high currents are mingling with very precise, microprocessor-controlled electronics, there’s no such thing as a “dead short”. Even one tenth of an ohm can cause major problems when it’s dismissed as not enough to worry about. When the current consumption of a high-power ignition system is combined with a bunch of high-current solenoids, the total current can exceed 30 Amps, or much higher. When you pass 30 Amps through a cable with a resistance of one tenth ohm, the voltage drop between the ends of that cable will be 3 VOLTS. A 3 volt change in sensor reference voltage rails can have many unpredictable results.

Unfortunately, one tenth of an ohm is as good as it gets in many situations. Even if you use a cable the size of your wrist, the crimped terminals on each end of it will result in a tiny bit of resistance. We must change our goal from avoidance to management. Given that some resistance is unavoidable, how does one minimize its impact on the operation of electronic devices?

A Little Science- OHM’s Law

Transients

The second demon in racing electronic systems is transient voltage. In electronics, the word “transient” is used to describe a short-duration condition triggered by an event. For example, when you remove power from an energized solenoid, a short duration (microsecond) pulse of high voltage is generated. This “spike” of voltage, when left uncontrolled, can wreak havoc on the microcontrollers in the system.

There are a lot of transient events in an automotive system, but the most concerning are those that generate a high voltage. This includes the ignition spark. Unmanaged, high-voltage spikes can cause problems that are very hard to troubleshoot. The effects are unpredictable and difficult to reproduce in testing. Transients are managed with preventative measures, rather than diagnostics.

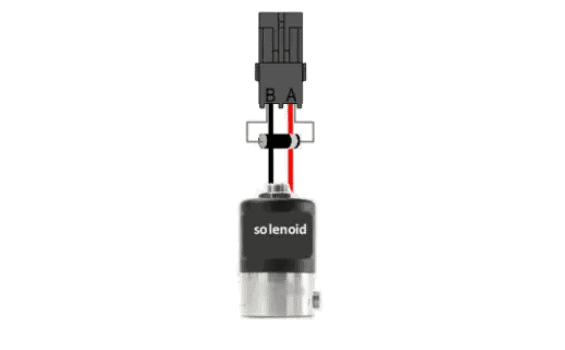

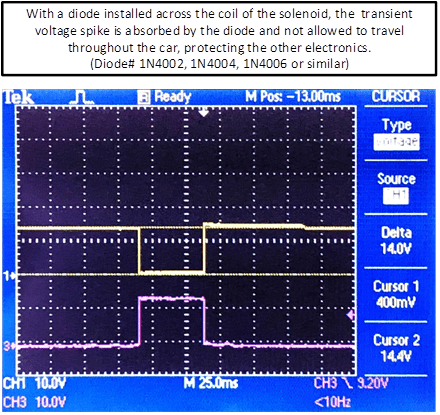

Transients are generated by power devices, such as solenoids, relays and coils, and most harmful to control devices. Transients can be managed with the use of diodes across the coils, as well as proper wiring techniques. Every solenoid or relay in the car should have a suppression diode installed, some relays, or controllers, MAY have the diode built, others may not. Simply changing a relay, could cost you weekends of failed racing. We recommend, and there is no harm in, adding a diode as insurance, not to mention it may improve the performance of a coil-driven device.

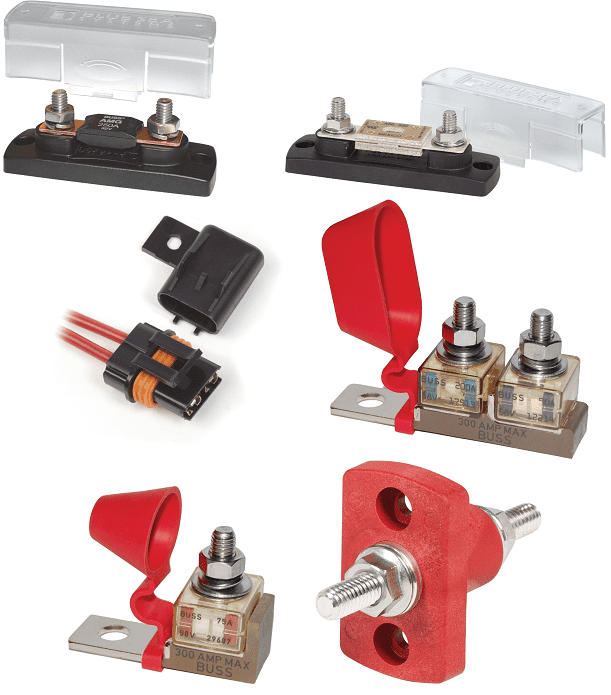

Examples of a couple of ways to possibly install a protection diode.

(Diode # 1N4002, 1N4004, 1N4006 or similar)

Example of a small air control solenoid producing a 396V transient voltage spike upon turning off.

Not hard to see how these voltage spikes can cause problems. These spikes can happen on either the positive or negative side, depending on the circuit. Just think of how your electronics feel about a 400 volt spike running through them.

Wiring

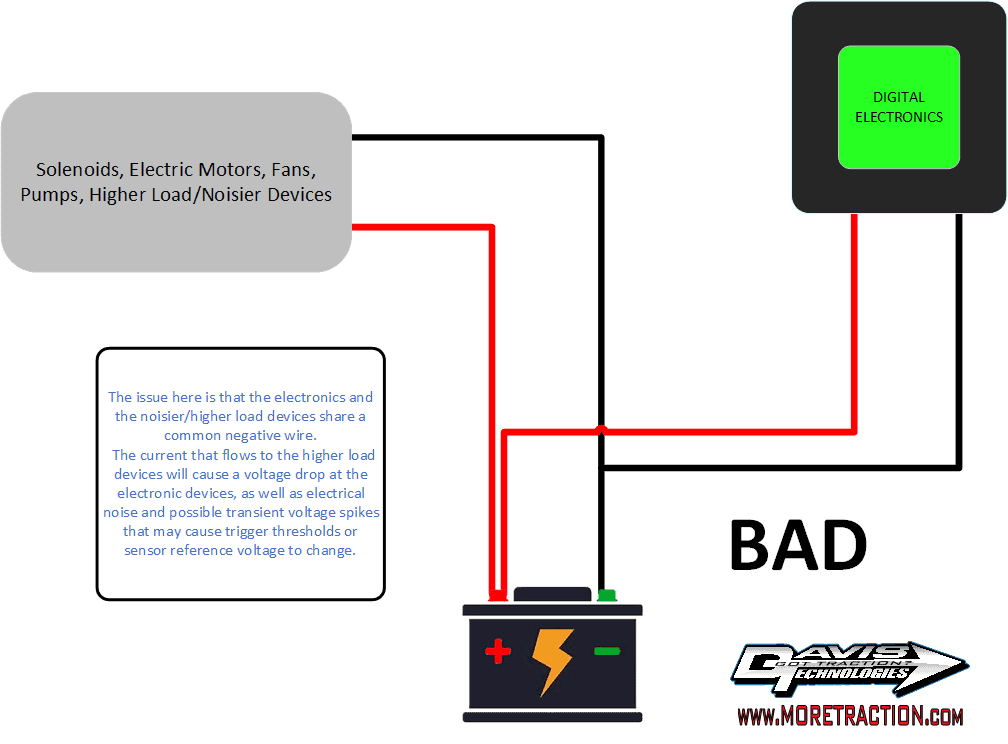

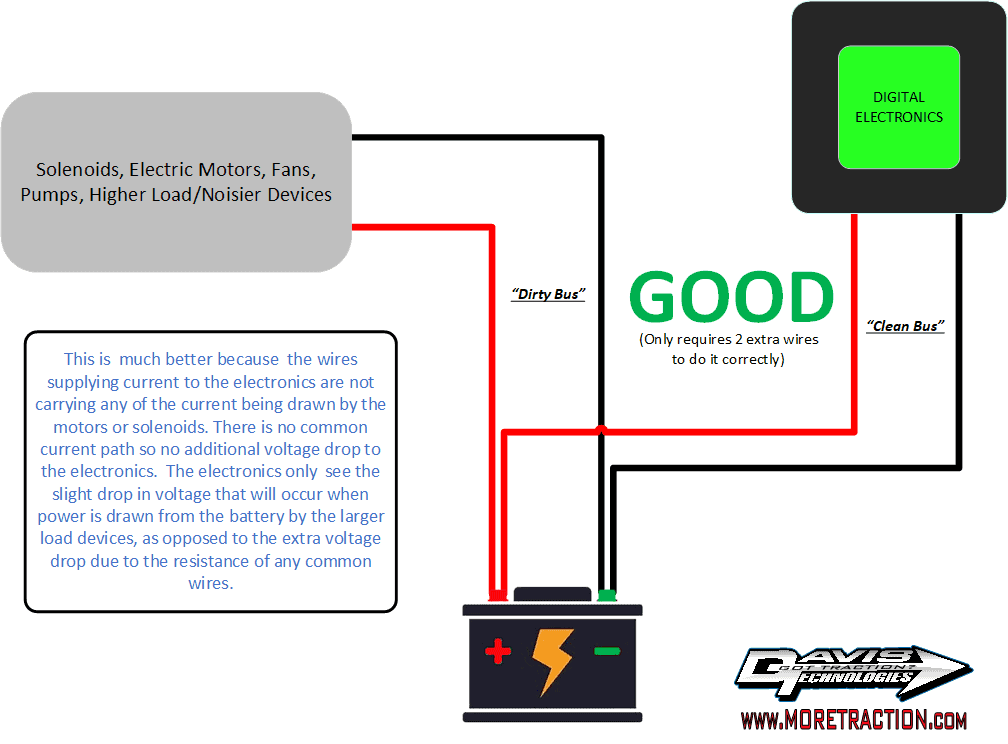

The general rule when wiring power and ground is to avoid sharing the connections between power devices and control devices. This is especially important for ground connections, but power connections should also be separate wherever possible. It is safe to assume that power devices generate the problems that control devices can’t tolerate. If the two categories of devices are connected to separate ground/power busses, it limits the transfer of problems from one to the other. Adding an additional ground wire to connect the 2 buses, a “common ground” like your “friend” suggested, is actually horrible. This may cause problems as opposed to fixing them— you CAN have too many grounds- especially if they go to the wrong places.

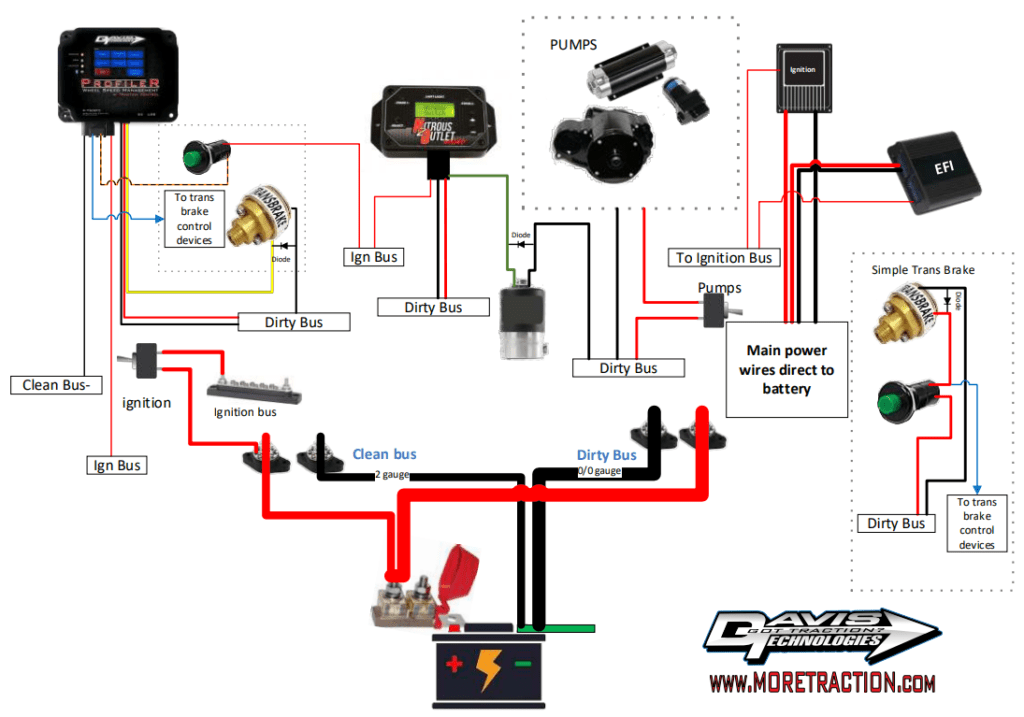

To this end, the best plan is to create a “Clean Bus” for the control devices and a “Dirty Bus” for the power devices. The goal of the clean bus is to minimize voltage drops, so it needs to be built with low-resistance cable and terminals. The goal of the dirty bus is to handle large currents, so it also needs to be built with low-resistance cables and terminals. In other words, use high-quality, low-resistance materials and methods for both. The 2AWG cable that handles 100 Amps without heating up will provide a quality ground reference when carrying 3 Amps for the control devices, a #10 AWG WILL NOT provide a sufficient ground path to the battery. This is not the place to save weight at the expense of unreliable operation of your electronics.

Chassis Ground

Dependence on chassis ground should be minimized. The chassis may be grounded to the battery negative terminal, providing a definite ground path to the chassis, not accidentally grounded through the engine or other purposefully grounded part. Grounding devices to the chassis should be avoided. Instead, ground them to the appropriate bus. The Clean Bus ground should not connect to chassis, ONLY TO BATTERY NEGATIVE TERMINAL!

Summary

In a perfect world, if the battery were safely mounted and protected in a central location, this would be best. As we all know, it is usually remotely located do to weight, rules, safety or other overriding factors. To be clear, every electrical device in the car should be grounded directly to the battery terminal. With the battery within reach, connecting the grounds properly would be easy, however, this is not realistic, so some compromise must be found.

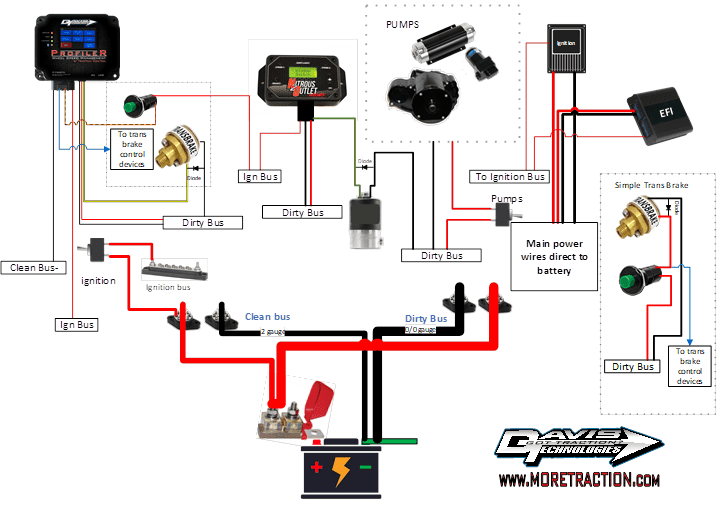

The best compromise is the separation of the grounds in the form of a “Dirty Bus” and a “Clean Bus”. The Clean bus can allow for a distribution block located in a more central area of the car for simpler wiring and neatness. This distribution block should be supplied with a large cable, like 1/0 gauge cable. Again, you may compromise and “get away” with a smaller gauge, but cable smaller than a minimum of 2 gauge should NOT be used. The larger wire size and a few ounces is cheap insurance against problems, aggravation and lost weekends. Plus, chicks dig big wires!

This Clean Bus Distribution block can be used as the voltage source for the various toggle switches and devices as well as the power source for the low current draw control devices like boost controllers, sensors, data loggers, traction control or ignition controls.

The Dirty Bus can allow for a distribution block located in a more central area of the car for ease of access. This Dirty Bus Distribution block can be used as the voltage source for things like solenoids, coils, or other high current draw devices. This distribution block should be supplied with a large cable (2/0 gauge or larger). Compromise here and suffer!

The main power leads for devices such as EFI boxes, Ignition Boxes or Coil Drives MUST be connected to the battery terminals or at worst to the Master kill switch located near the battery! Almost every manufacturer specifies this and it is very important for reasons you will see below.

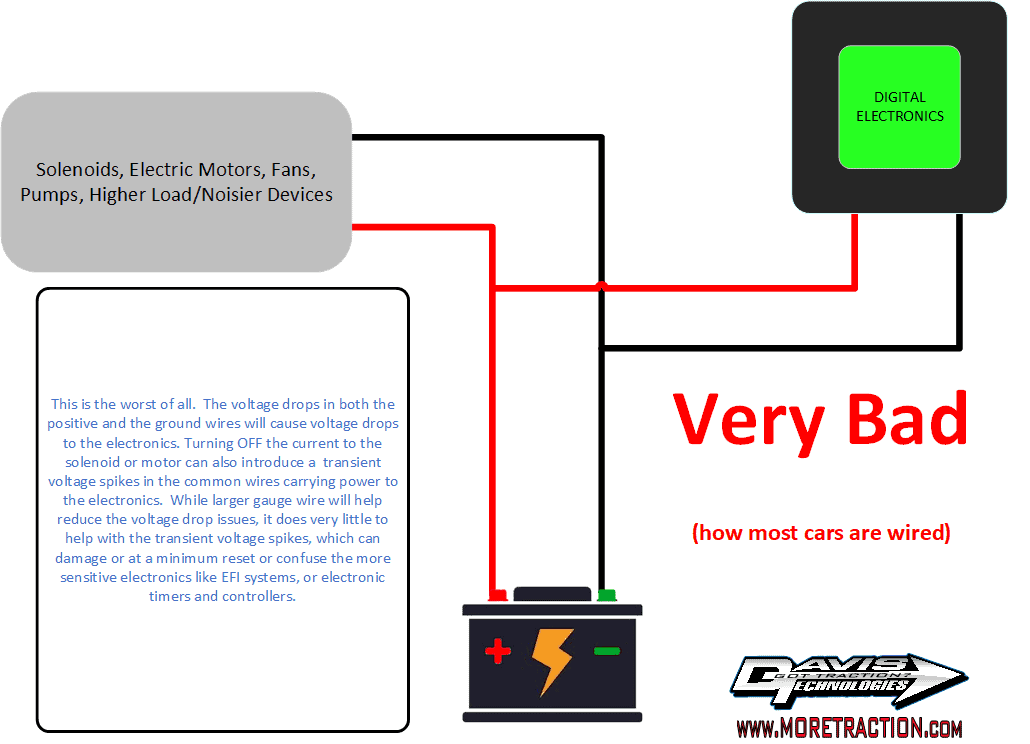

Here are a few different ways of wiring a simple circuit with a battery, a motor or solenoid and an electronic device. To keep things simple, only the major components are shown. Electrically they are all the same in that they are all connected to positive and negative and will turn on/off. Electronically, however, the example labeled Bad, and Worst are likely to cause problems and lots of aggravation! The one labeled Good will probably work, but Best is the way it should be done. If your wiring guy is not following the simple methods shown in the Best example- get someone else to do it.

Running a pair of large gauge wires from the battery to distribution blocks and connecting EVERYTHING to those blocks is VERY BAD!!!

It may look good and be easy- but, it will NOT work properly. As shown in the Best example, the proper method is to have a “Clean Bus” with only electronics connected to that bus, and a “Dirty Bus” with the higher current draw and noisier devices connected to that bus.

Important Notes-

- Use the proper gauge wire

- EVERY solenoid should have a protection diode installed- even if you have never heard of that!

- Do Not depend on the chassis to be a proper ground

- Ground each cylinder head to the battery ground (Dirty Bus)

- connect each cylinder head to coil negative post if compatible.

- Since the chassis will probably get a partial ground from the engine- Run a grounding strap from Dirty Bus ground to chassis to make sure it is properly grounded.

- Stay away from Butt splices- just don’t use them.

- Ignore your buddy who says “I never did that and mine works fine”

- When connecting or disconnecting a battery charger the Master switch should be off. Do not leave it on and all electronics connected and powered up when connecting and disconnecting the battery charger. Furthermore powering up electronics rated for 12-16 volts with a battery charger that’s humming along at a much higher voltage is not good for the electronics.

The main power wires of these devices should be connected to the Battery Terminals.

- Ignition Boxes (main power wires- not the on/off ignition wire)

- Injector Drivers (main power wires- not the on/off ignition wire)

- EFI (main power wires- not the on/off ignition wire)

Here is a list of devices commonly found in racecars that can cause problems to electronics wired to the same circuit. The main power wires of these devices should be connected to the Dirty Bus.

- Starter motors/starter solenoids

- Solenoids

- Relays

- Pumps

- Electric Blowers

- Electric fans

- Headlight bulbs

These devices should be connected to the Clean Bus.

- Traction Control

- Ignition On/Off

- EFI On/Off

- Boost Controllers

- Shift Controller

- Timers

- Data Loggers

- Dash

- Sensors / Instruments